On September 12, 2025, the four-day Shanghai Home Expo and WMF International Woodworking Exhibition came to a successful conclusion at the National Convention and Exhibition Center. Guangdong Hanqiu Intelligent Equipment Co., Ltd.'s integrated coating solution with the theme of "able to roll, spray, and press paste" shone at the exhibition, injecting new energy into the industry for intelligent upgrading.

Highlights

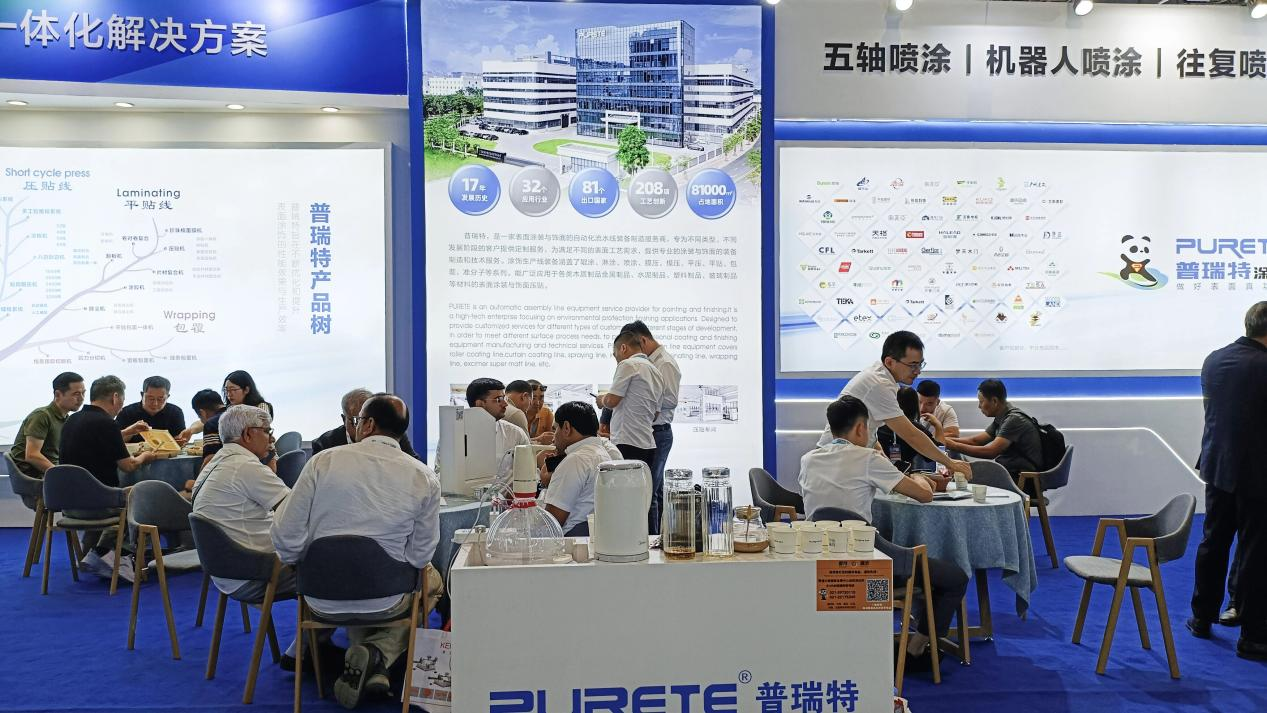

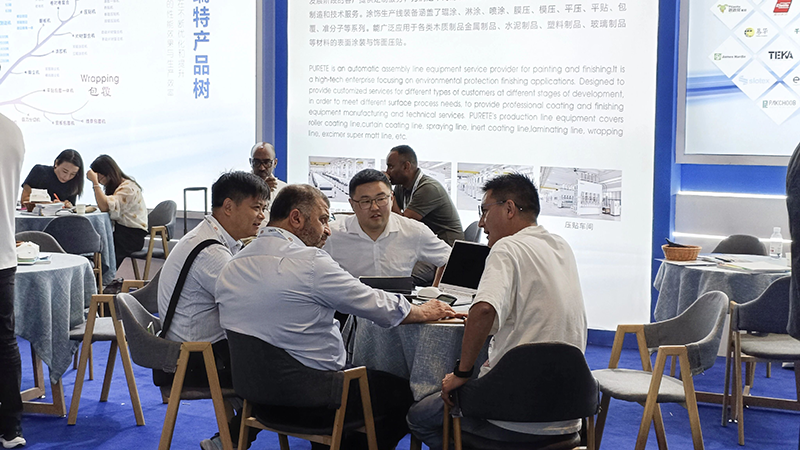

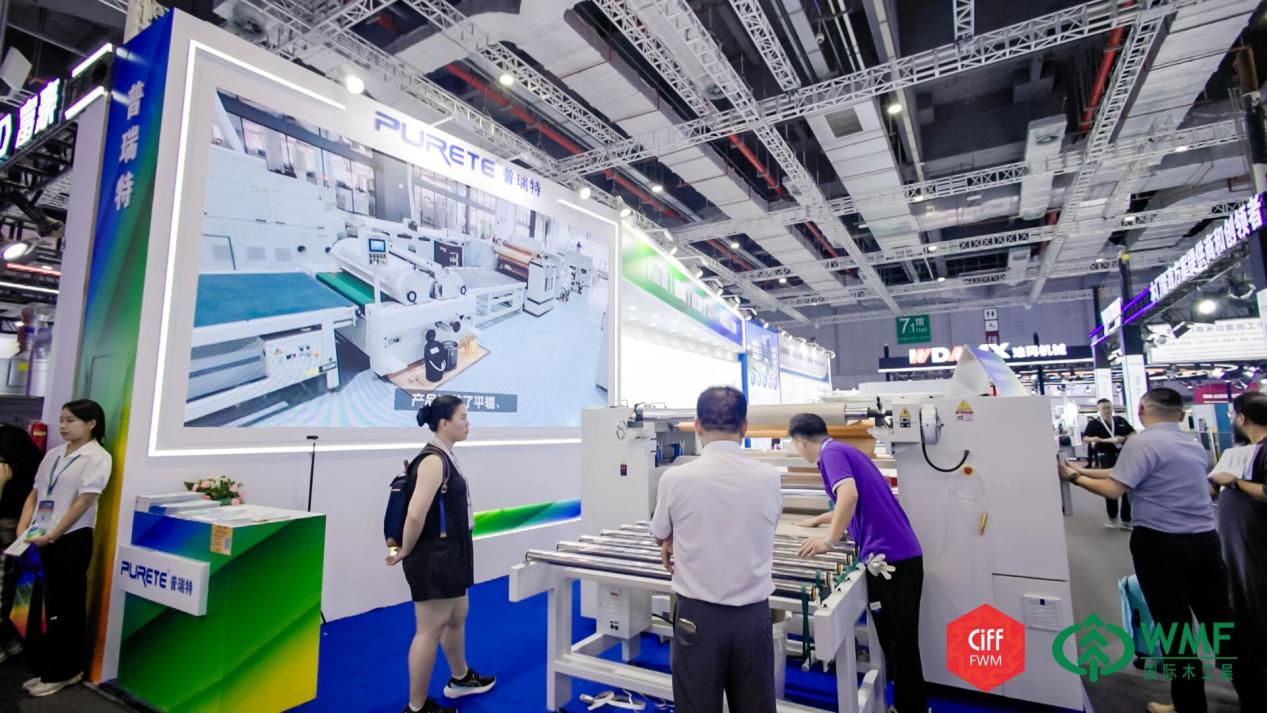

Throughout the exhibition period, the booth of Guangdong Hanqiu remained extremely popular, attracting professional visitors from all over the world to come and consult and experience. The integrated concept of "roller, spray, and pressure coating" has become a high-frequency keyword on site. The on-site staff provided a detailed introduction on how the intelligent spraying system achieves the dual goals of "efficient production+cost reduction" by intelligently adjusting the amount of paint used.

Multi material innovative technology release

One of the highlights of this exhibition is undoubtedly the speech by Chen Zejin, General Manager of Hanqiu Group's Business Unit, at the China (Shanghai) International Furniture Production Equipment and Woodworking Machinery Exhibition on the release of "Innovative Technologies for Diversified Materials". Directly addressing the production challenges of "diversified materials and complex craftsmanship" in the current furniture industry. In his speech, Mr. Chen pointed out that with the increasing diversification of consumer demands, traditional single material and single style home products are no longer able to meet market demand, and personalized and customized needs are gradually becoming mainstream. Pruitt's advocacy of "diverse materials" includes four major substrates: metal products, plastic products, wood products, cement products, etc., and provides a rich variety of coating and finishing solutions for these substrates.

Can roll | can spray | can press stick

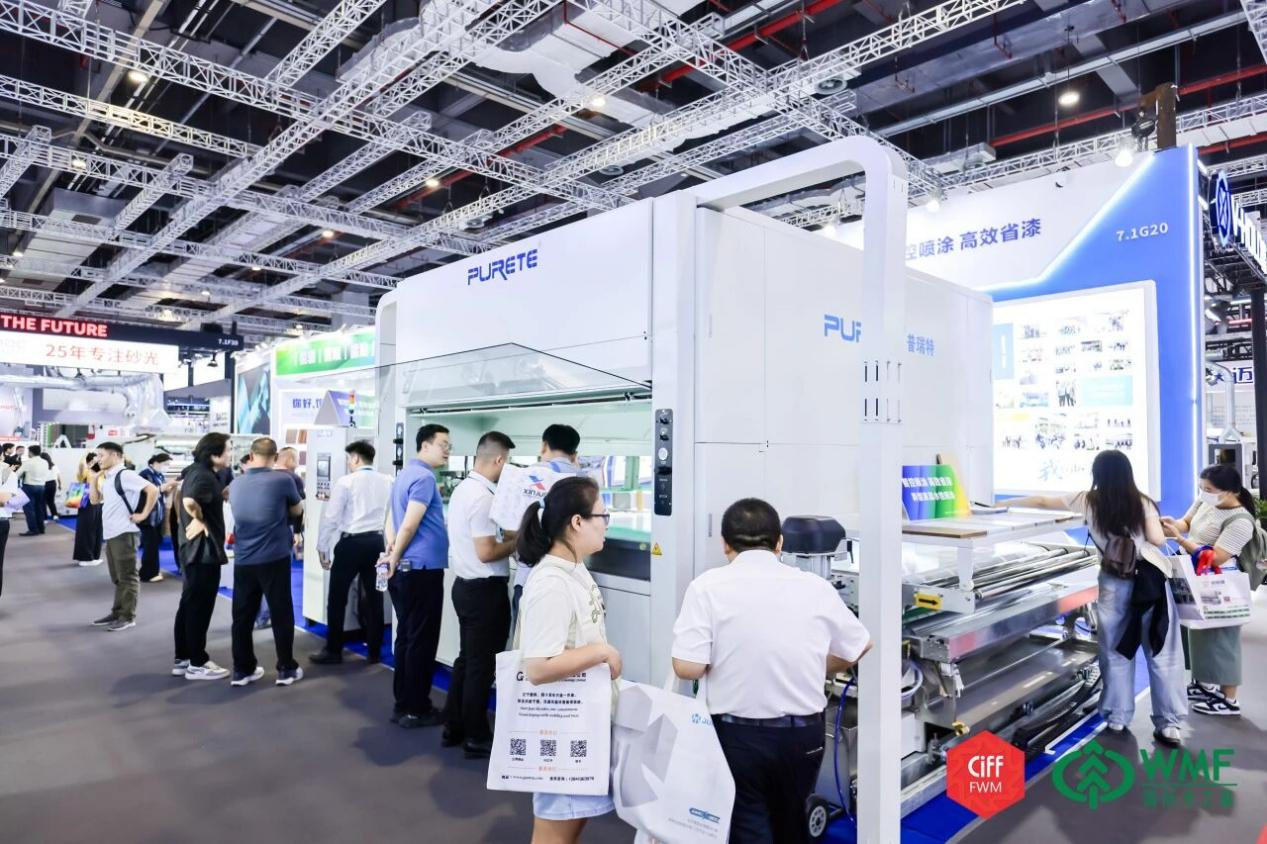

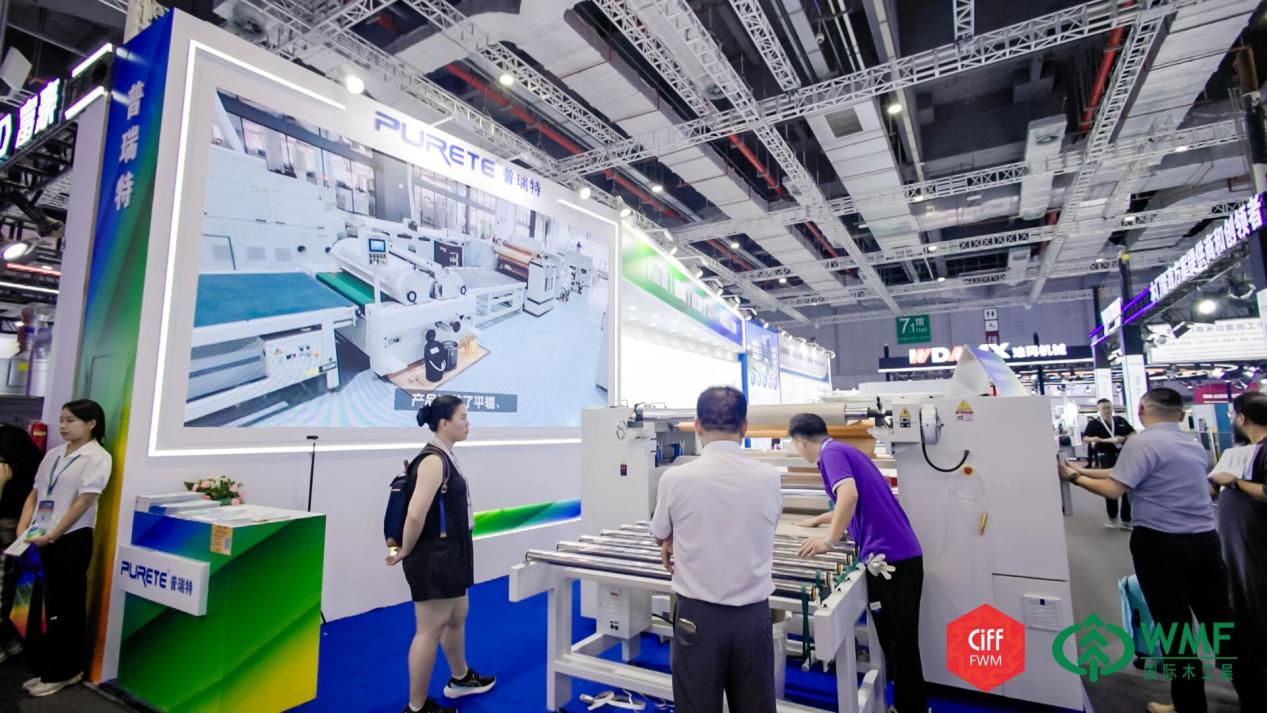

At this exhibition, Hanqiu's reciprocating spray paint machine and PUR flat line, as the core equipment of the "integrated coating solution," won widespread praise from customers.

1. Reciprocating spray paint machine: efficient and energy-saving, stable and reliable

The Pruitt reciprocating paint spraying machine adopts an intelligent paint control system, which can automatically adjust the spraying parameters according to the size and material of the workpiece, avoiding paint waste. Compared with traditional equipment, it can save more than 20% of paint; At the same time, the equipment is equipped with high-precision guide rails and servo motors, with a spraying accuracy of ± 0.1mm, ensuring that the coating of each workpiece is uniform and smooth, solving the problem of "large color difference and low efficiency" in manual spraying. Whether it's large-scale sheet metal spraying or complex shaped workpiece operations, it can be easily handled.

2. PUR flat adhesive thread: Strong adhesion, environmentally friendly and durable

PUR flat adhesive line focuses on the upgrade of "bonding technology", using environmentally friendly PUR hot melt adhesive, which does not release formaldehyde and meets national environmental standards; During the bonding process, intelligent temperature control and pressure regulation are used to ensure even distribution of the adhesive layer. The bonding strength is 30% higher than traditional cold bonding, and it has stronger temperature and moisture resistance. Even in humid environments, it is not easy for the adhesive to peel off. In addition, the equipment also supports the bonding of various veneer materials (such as PVC, PET, wood veneer, etc.) to meet the production needs of furniture enterprises for "one function, multiple uses".

Closing ceremony and departure

The conclusion of the Shanghai WMF International Woodworking Exhibition is another milestone for Guangdong Hanqiu's deep cultivation in the field of coating equipment, and it is also a new starting point for us to move towards the future. Although the exhibition has come to an end, Pruitt's path of innovation has never stopped. The company's 3000 square meter coating experience center located in Shunde and over 30 carefully developed new coating processes will continue to showcase the charm of the industry's forefront to customers.

Looking forward to the next gathering and witnessing Pruitt bringing more innovative technologies and solutions! Innovative coating technology, creating a better life together!